Industrial, Commercial & Civil Abrasive Blasting Gallery

Large tanks (16m long x 5m diameter)

Abrasive blast, Epoxy prime, Polyurethane top coat

Before, blasting, priming and top coating

Marion Council back up Generator

Before treatment, during treatment and after treatment

Spot blast to remove corrosion, Zinc epoxy prime spot blasted areas, Full hand prep, Full coat of epoxy primer, Full top coat of Poly urethane

Recent Jobs – Industrial & Commercial Gallery

Gas pipe work that needs the corrosion removed by blasting and then painting for a Gas field in West Australia

A variety of different types of Gas pipes that need to be blasted and then surface coated for a Gas field in West Australia

A gas company needed 150 different lengths of pipe sand blasted and under coated and then top coat applied

Pressure vessels which have been abrasive blasted and then power coated in different colours to denote different uses.

Truck bin on tip truck which was abrasive blasted, epoxy primed and Poly urethane top coat applied whilst still attached to the truck – before

Truck bin on tip truck which was abrasive blasted, epoxy primed and Polyurethane top coat applied whilst still attached to the truck and the company signage applied – after

A Steel Gas gas pit which has undergone restoration. These Gas pits are installed underground and are used to regulate the flow of gas

Two radial water gates which are used to control the flow of water in the River Murray have been sand blasted Undercoated and industrial coated

A radial gate which has been sand blasted and undercoated. These Radial gates which are installed by SA Water on Hindmarsh Island separate the Murray river water from the sea water. These gates are 30 0r 40years old and 30 water gates are restored every year and there are 300 of them installed

Industrial large fire extinguishers that have been resprayed red, loaded on a pallet ready for delivery

Water control Barges form the Murray river which are dissembled abrasive blasted undercoated and spray painted with three top Coats

Shipping containers that have been converted to communication centres for the Australian which are being prepared for respraying

panels that are part of generator boxesplant that have been restore via abrasive blasting and surface coating

Louvres and door frames that are part of generator boxesplant that have been restore via abrasive blasting and surface coating

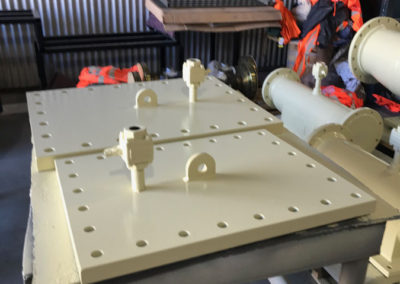

Flange panels for supporting new piping for mining in outback Australia. Delivered after being newly fabricated and nartchhave undercoated and surface coated

Defence force portable communications centres that will be surface coated to withstand the harsh conditions they operate in

A Radial gate used to control water flow at the mouth of the river Murray after being abrasive blasted

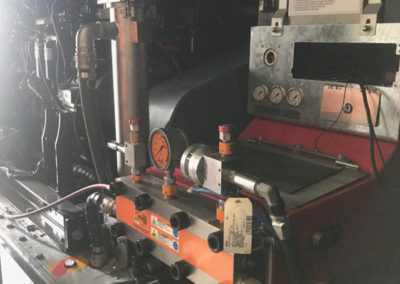

This part High performance abrasive recovery system is the vacuum unit will which will be mounted on a trailer for mobile work

This part High performance abrasive recovery system is the storage hopper unit will which will be mounted on a trailer for mobile work

The storage hopper unit has a frame which makes it stable and can be mounted on a trailer for mobile work

Hartech has purchased this High performance abrasive recovery system has the capacity to vacuum spent abrasives at the rate 3 ton an hour

The hull of the One and All Tall ship after there was 5 coats of paint were applied including 3 coats of ozone coating (primer/sealer) plus two coats of anti fouling

One The Hartech mobile abrasive blasting and spray painting trucks which enable Hartech to undertake large commercial and industrial abrasive blasting and spray painting work

The restoration of the hull of the One and All Tall ship Is one of the abrasive blasting and painting jobs that Hartech is most proud of.

Straight gas pipes in standard length that have been abrasive blasted under-coated, surface coated a safety red colour wrapped in plastic ready for shipment

Showing the inside capacity gas storage sumps that have been abrasive blasted undercoated and then powder coated both on the inside and outside

This photo shows a different perspective of the sections of material that Hartech have been undertaking testing on. For a new type of surface coating developed at Adelaide university.

Hartech have been undertaking testing of a new type of surface coating developed at an Adelaide university. This photo sections drying

Long Straight sections of gas pipes that have been abrasive blasted under-coated before surface coating

A variety of L-shaped or right angle sections of gas pipes that have been abrasive blasted under-coated before surface coating

Showing the corrosion which needs to be removed by abrasive blasting from the underside of an individual Radial gate used in water barrages. 300 will have anti corrosion treatment

Variety of industrial pipes and radial gates for barrages being sorted into what type of blasting is to be used on each item

3 Radial gates for barrages which have been loaded onto trolleys before blasting, The Radial gates for barrages are used for adjusting water flow in the Murray River in the Coorong area

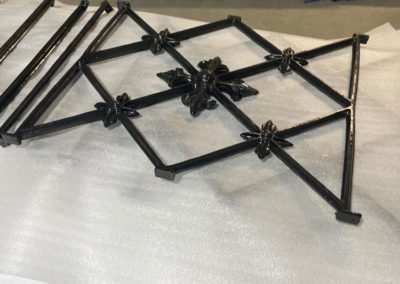

Prison doors which have been painted with 2 pack epoxy paint, applying 2 coats of 750 microns in three different Colours which have significance in New Zealand prisons

Vision panels and gas elbow pipes which have been painted different colours hanging in the drying room

Vision panels for prison doors and gas elbow pipes which have been painted hanging in the drying room

New Prison doors which have been painted with different coloured 2 pack epoxy paint manufactured in South Australia, packaged for delivery to New Zealand

Two Gas valve pits which have been blasted, the bottom one has been undercoated and one stacked on top has had a green topcoat applied

Gas valve pits which are used as connectors and buried underground which have restored to prevent corrosion, showing the inlet view

Pipe being abrasive blasted, there are a variety of different sized pipes including elbow pipes and pipes of different lengths and sizes which are use by industrial gas piping

Gas and water piping which have been labelled to enable staff to carry out the correct abrasive blasting and surface coating

Gas and water pipes which will be blasted to 2.5 to 3 Australian standard blasting and then wet sprayed

Elbow pipe risers used for domestic and industrial Gas supply, surface coated with heavy duty high build surface coating which will have dense tape applied followed by a water proofing membrane because they need to be buried under the ground. With these applications after 50 years buried in the ground they still look like new

PH: 08 8340 3477

PH: 0409 695 469

EMAIL: hartech@bigpond.com

ADDRESS: 34 ADAM ST, HINDMARSH, SA, 5007

Pick up and delivery service available

Nace Coating Inspector Level 1 – Certified, CIP No. 13390

Trading Hours:

Mon - Thurs: 6.00 am - 3.00 pm

Friday: 6.00 am - 2.00 pm

Front entrance to Hartech - 34 Adam Street, Hindmarsh S.A.5007

Follow Us on Social Media:

Rear entrance to Hartech - 8 River Street, Hindmarsh S.A.5007